![]()

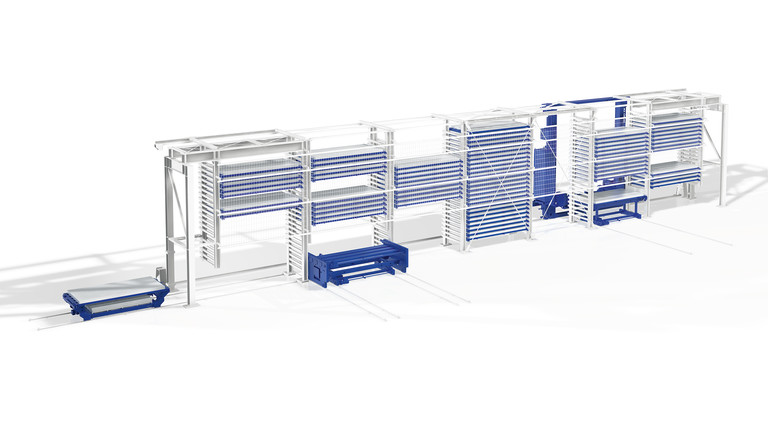

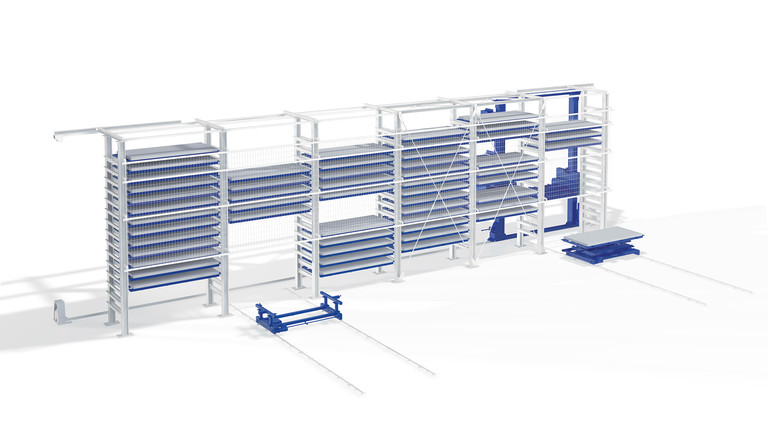

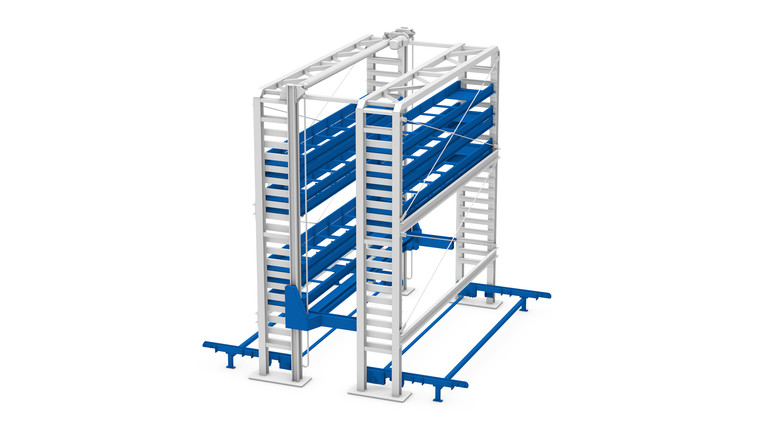

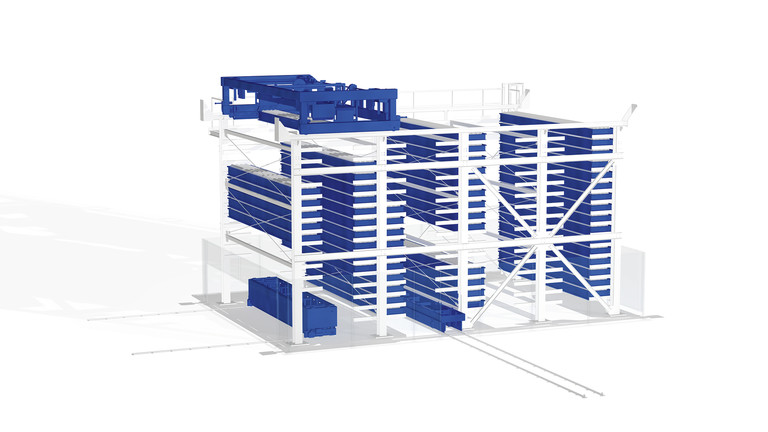

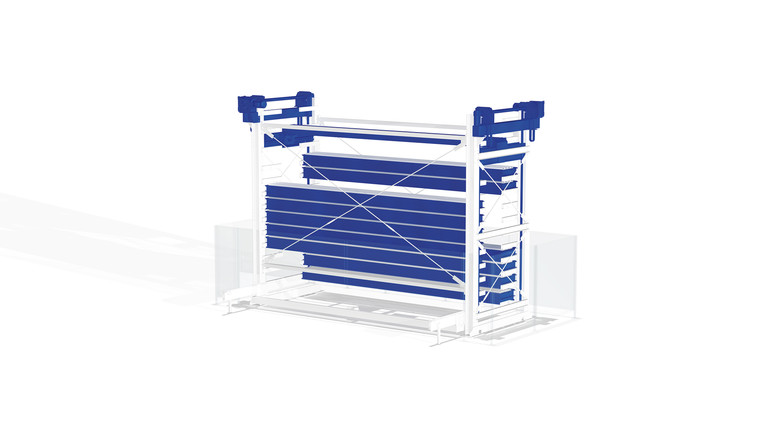

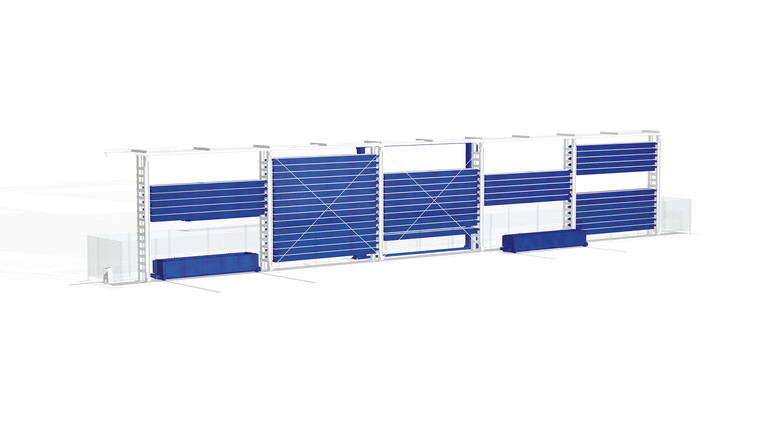

STOPA ist europaweit führender Premium-Hersteller von automatisierten Lagersystemen für Bleche, Langgut und Parksystemen. Die Angebotspalette reicht von Stand-Alone-Anwendungen bis zu integrativen Automatisierungsmodulen. Wir besitzen ein einzigartiges Knowhow hinsichtlich Produktqualität und Prozesssicherheit, Prozessautomatisierung und Softwareentwicklung.

Karriere

Stellenangebote

Ausbildung

Mit STOPA erleben unsere Kunden eine verlässliche Materialbereitstellung mit hoher technischer Verfügbarkeit und deutlich reduzierten Suchzeiten. Basis dieser Leistung sind die hochwertigen Einzelkomponenten und die massive Bauweise, verbunden mit der Ersatzteilverfügbarkeit eines Herstellers aus Baden-Württemberg.

3 Gründe für STOPA

Jede Lösung ein Unikat

Lösungen von STOPA sind in hohem Maße anforderungsspezifisch und kundenindividuell. Geschmeidig passen sie sich jedem Konzept der Lagerung und der Materialbereitstellung an. Für mehr Planungs- und Zukunftssicherheit.

Intelligente Automatisierung

Weltweit über 2000 installierte Anlagen – daraus bezieht STOPA ein einzigartiges Know-how in der Automatisierung intralogistischer Prozesse. Eine eigene Softwareplattform liefert Schnittstellen zu Werkzeugmaschinen und Anlagen.

Immer an Ihrer Seite

Die Experten von STOPA sind immer in Ihrer Nähe. Von der Bedarfsanalyse, über Best-Practise-Empfehlungen bis zur Produktionsbegleitung, präventiver Wartung und Anlagenmodernisierung. Damit Sie immer das gute Gefühl haben, mit den Besten am Tisch zu sitzen.