STOPA Warehouse management software

The smart choice

Maximize your warehouse potential with STOPA‘s Warehouse Management software.

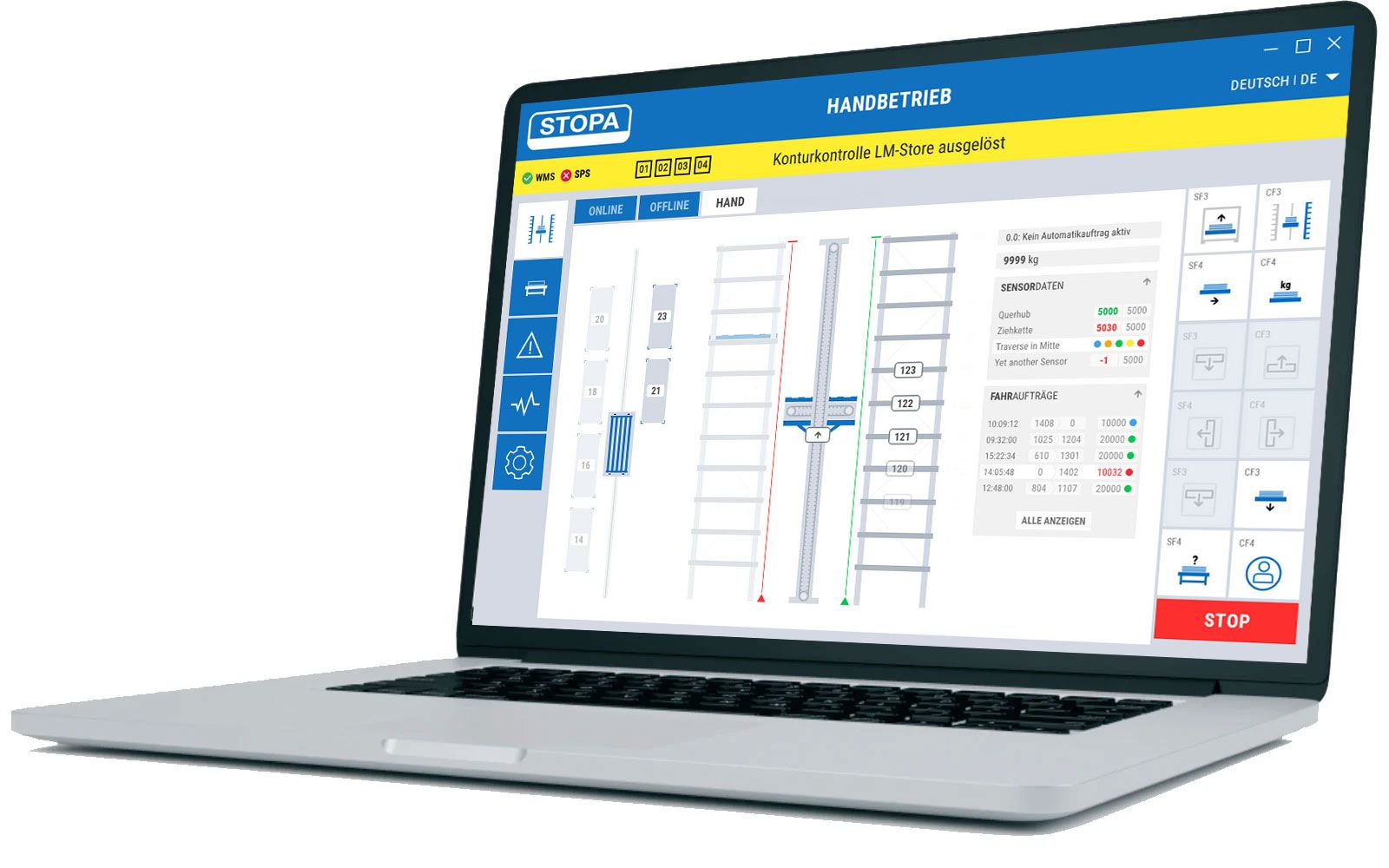

This intuitive software serves as your personal assistant, helping you boost productivity and minimize errors. Whether you‘re monitoring your inventory and movements, managing different warehouse zones, or simply aiming to enhance efficiency. Configure your warehouse according to your preferences, and STOPA will handle the rest.

STOPA‘s modular software design allows for tailored solutions for each of your warehouse requirements. Choose between the versions “WMS-Essential,“ “WMS-Tower 4.0,“ “WMS-Basic 4.0,“ or “WMS-Extended 4.0“ and benefit from functionalities that perfectly match your needs.

An added bonus: you can upgrade at any time if necessary.

BENEFITS AT A GLANCE

-

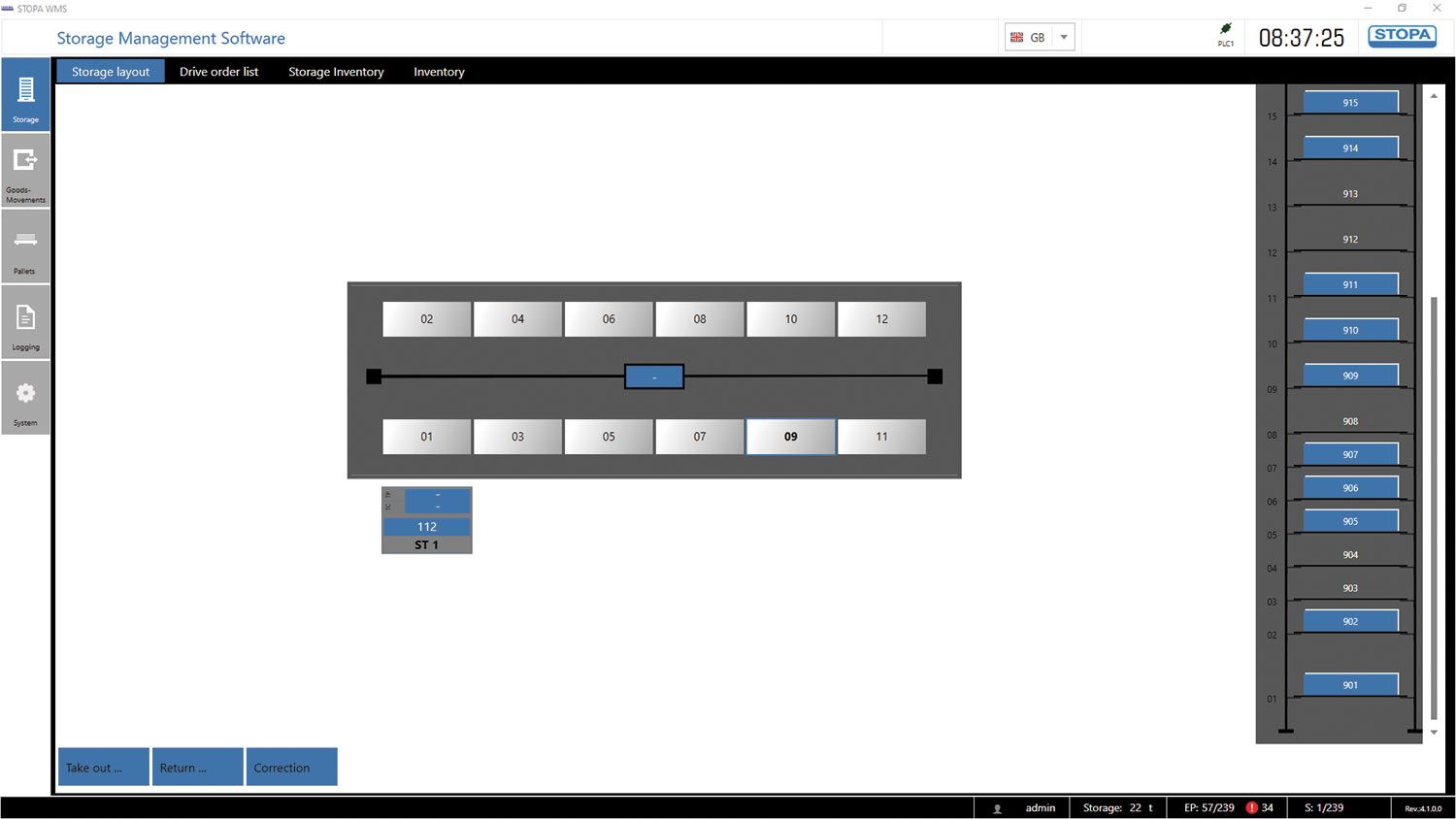

Efficient management of any number of storage places and areas (for sheet metal and long-span storage systems). Clear and intuitive user interface.

-

Clear and intuitive user interface.

-

Static and/or dynamic storage, configurable for every compartment and pallet.

-

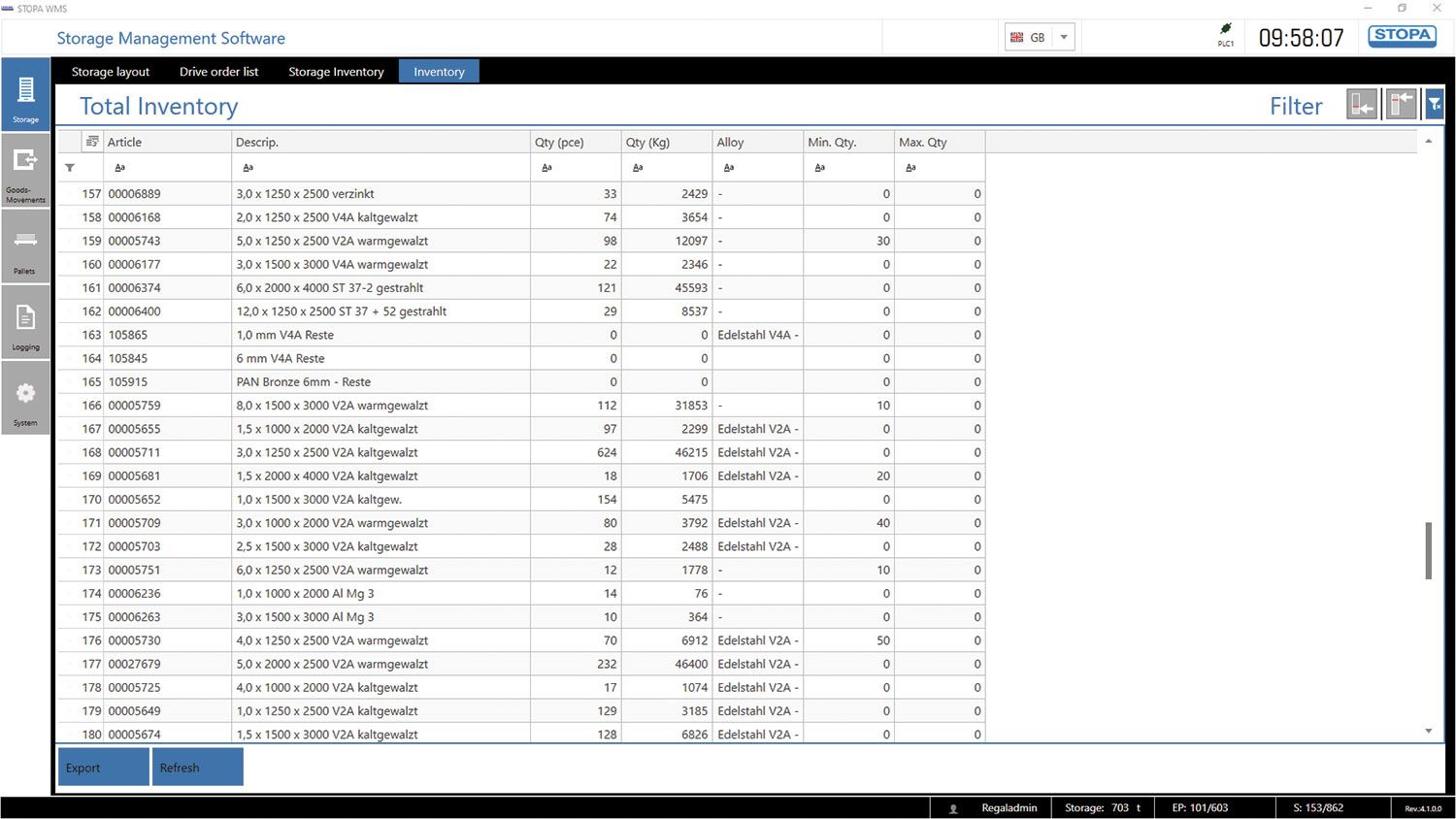

Logging of all storage movements and recording in a booking journal.

-

Management of multiple warehouse zones possible, e.g., for separating stainless steel from carbon steel.

-

Batch-accurate management of inventories and residual stock management.

-

Blocking of storage places, articles, or individual batches possible.

-

Storage, additional storage, relocation, full withdrawals, and partial withdrawals.

-

Automatic piece count determination through integrated weighing facility (optional).

-

Interfaces for the integration of production machines.

Softwaredesign and versions

Opt for more efficiency – with the warehouse management software from STOPA!

WMS-Essential

The “Essential“ WMS version for STOPA ECO PLUS and STOPA LG-E storage systems provides you with all the functions necessary for operating a single-tower or double-tower warehouse as a fixed-place storage. In fixed-place storage, each pallet is assigned to a fixed storage location. The loading heights are also fixed and are assigned during the warehouse configuration.

WMS-Tower 4.0

“WMS-Tower 4.0“ enables efficient management of single or double-tower storage systems by STOPA. The software works with a fixed storage location assignment for each pallet. The loading heights are constant and determined during the warehouse setup.

WMS-Basic 4.0

WMS-Dynamic 4.0

Your CONTACT PERSON

Dieter Ruh

Software development

STOPA Anlagenbau GmbH

Industriestr. 12

77855 Achern-Gamshurst

Tel +49 7841 704-149

Fax +49 7841 704-190

service@stopa.com

ENQUIRY

Contact

STOPA Anlagenbau GmbH

Industriestraße 12

77855 Achern-Gamhurst