STOPA Tower Eco plus Sheet Metal Storage Systems

Maximum modularity right from the beginning

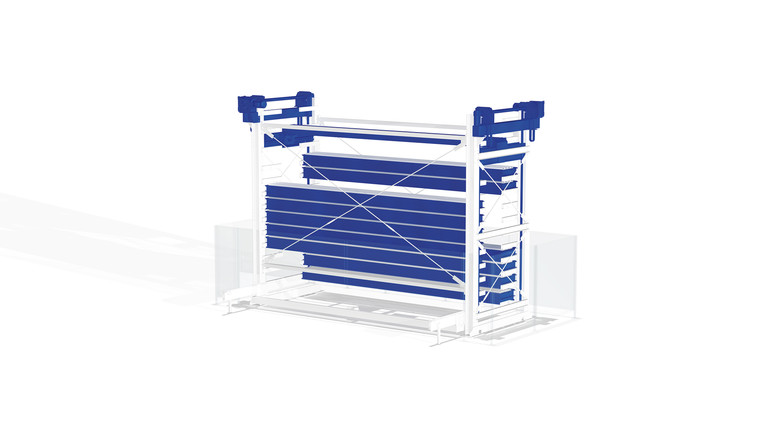

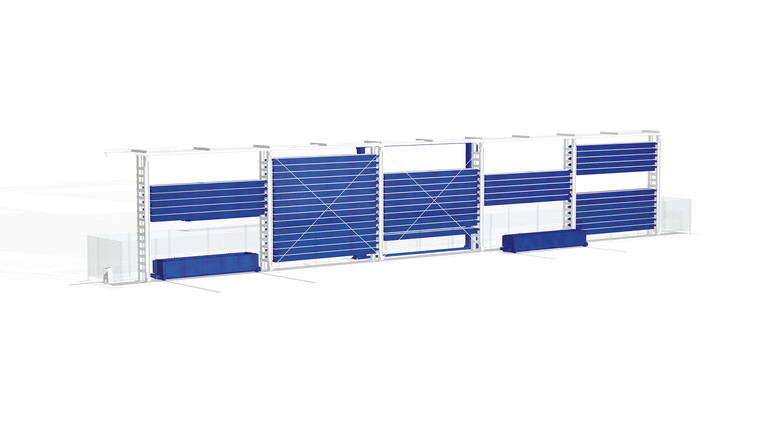

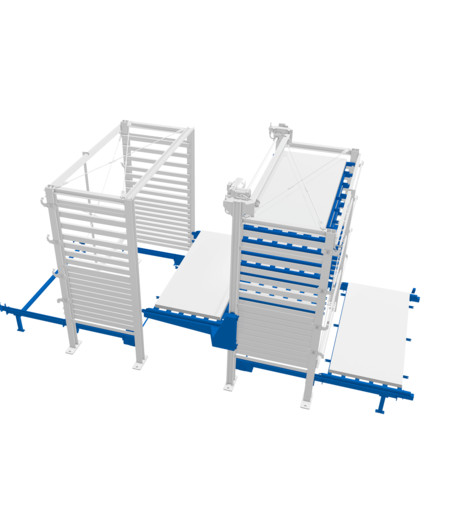

Getting started in automated storage has now been made even easier with an exciting variant. That's because the new STOPA TOWER ECO Plus allows customers to benefit from high flexibility too: they have the option of expanding it using modules at any time to keep pace with growing needs for storage capacity. To do so, the components for expansion are versatile and intelligently designed, in both hardware and software. For example, a second storage tower, an additional chain conveyor that's simply bolted on, or a transport cart can be installed step by step.

The STOPA TOWER ECO Plus is designed to meet the needs of companies of any size.

Even the basic version, made up of a storage tower and a lifting beam, is already geared to the future and prepared for the addition of prefabricated mechanical components, for example with holes. Additional sensors can be fastened to the beam using these holes. The sensors check the storage process in the second tower.

The STOPA TOWER ECO Plus scores points with a capacity designed for fast turnover rates, in other words for growth. It almost matches the capacities of large-scale storage systems.

STOPA has integrated the system control panel compactly into the switch cabinet, meaning that the user doesn't require any addition al hardware. Moreover, STOPA has prepared as a standard feature the integration of warehouse management software that communicates with the user's ERP system. Customers who only require a simple stock management system will find it in the basic version.

| STOPA Tower Eco plus | Pallet format GF | Pallet format XF |

|---|---|---|

| Size W x L [mm] | 3.048 x 1.524 | 4.054 x 2.032 |

| Effective payload per storage location [kg] | 1.500-3.000 | 3.000 |

| Max. lifting speed [m/min] | 16 | 16 |

| Max. pulling speed [m/min] | 12 | 12 |

| Max. No. of pallets (single tower + loading height 50) | 49 | 39 |

| Max. total height | 7950 | 7950 |

| Loading heights (max. 3 different heights)[mm] | 50, 60, 90, 130, 200 | 50, 60, 90, 130, 200 |

| Building-support design | no | no |

| Full integration, sheet metal processing machine | no | no |

* Special heights are available, upon request

Equipment overview STOPA Equipment

More systems

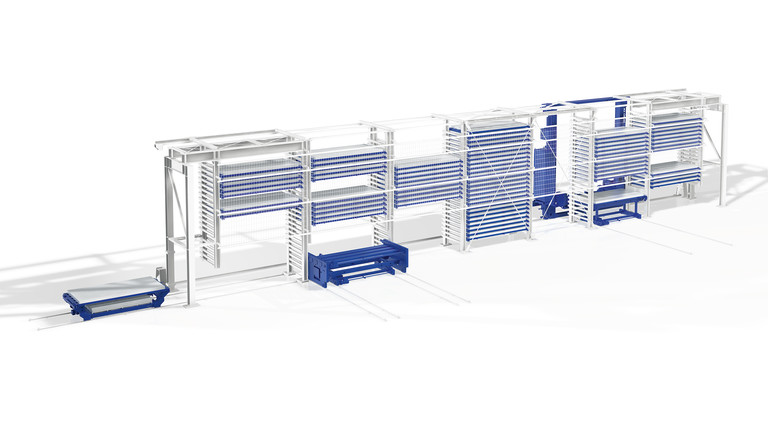

STOPA Compact Series System features

- Large-scale storage system with pull technology

- Single or double-rowed models

- Goods carriers: Pallet or cassette with rollers

- Available for all standard sheet metal formats and multi-format storage systems*

- Automatic operation

- Entry / exit of the stations at all openings (on the face and longitudinal sides)

- Automatic linkage of machines possible

- Chaotic storage management with STOPA Storage Management Software (SMS)

- Linkage to supervisory computer system possible

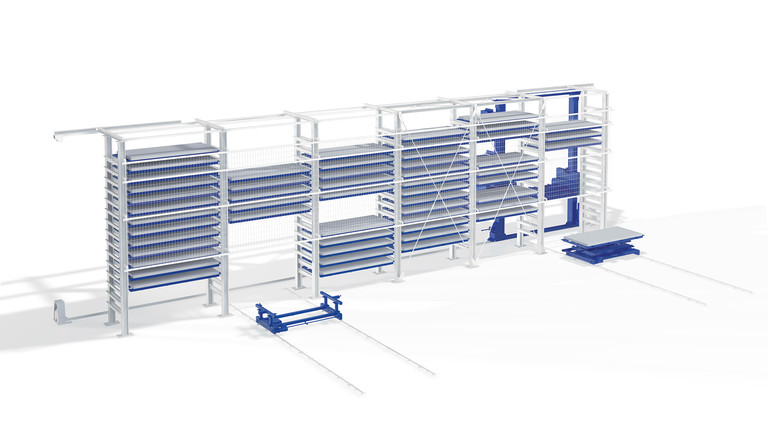

STOPA Universal System features

- Single or double-rowed storage system

- Goods carriers: Pallet or cassette

- Effective payload: 3,000 kg or 5,000 kg

- Available for all standard sheet metal formats and multi-format storage systems*

- Max. system height: Dependent upon on-site conditions!

- Automatic operation

- Automatic linkage of machines possible

- Chaotic storage management with STOPA Storage Management Software (SMS)

- Linkage to supervisory computer system

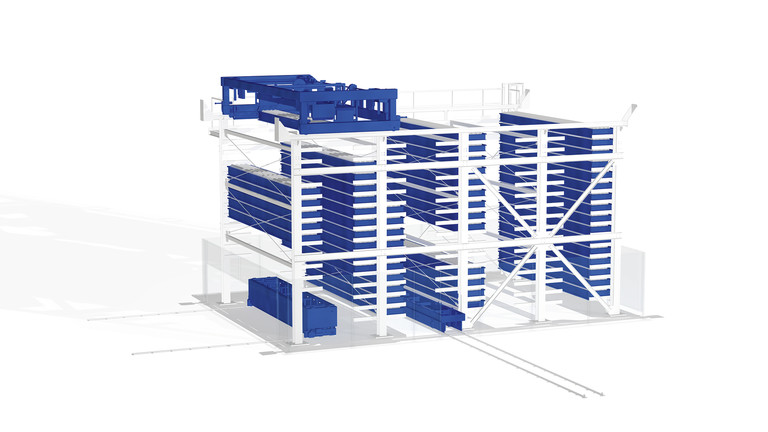

STOPA Tower Flex System features

- Single- or double-sided storage system in the form of a tower with pull technology

- Goods carriers: Pallet or cassette with rollers

- Effective payload: 3,000 kg or 5,000 kg

- Available for all standard sheet formats*

- Optional: Linkage of machines

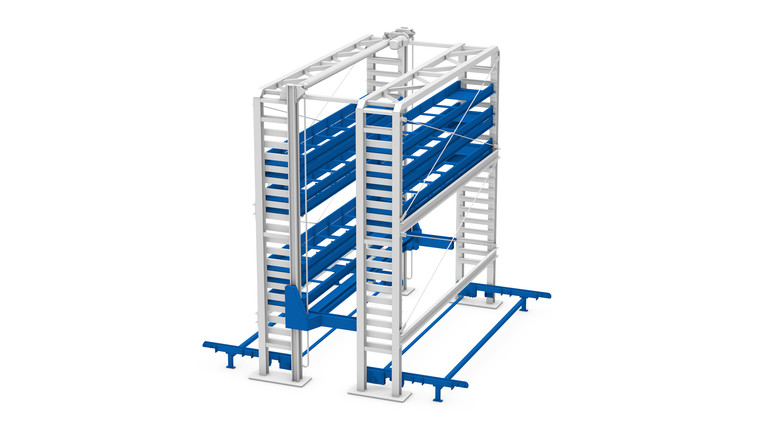

STOPA Tower Mono System features

- Single-sided storage system by way of a tower with pull technology

- Goods carriers: Pallet with rollers

- Effective payload: 3,000 kg or 5,000 kg

- Optional: Automatic operation

- Removal of the material directly from the load bar

- Available for all standard sheet formats*